Development of compressed materials

Finding the right formulation

It is essential to use a formulation adapted to the final use of the granules in order to obtain a material that meets our customers’ specifications (granulometry, density, hygrometry, etc.).

In order to do this, our research and development department works with our technicians during the test phases. This allows us to reduce delays and therefore costs.

Once the right formulation is chosen, our production line starts to produce the compressed granules.

Preparation of the compound blend

To obtain consistent quality granules, we mix the raw materials of the formulation to obtain a homogeneous blend with a controlled hygrometry rate.

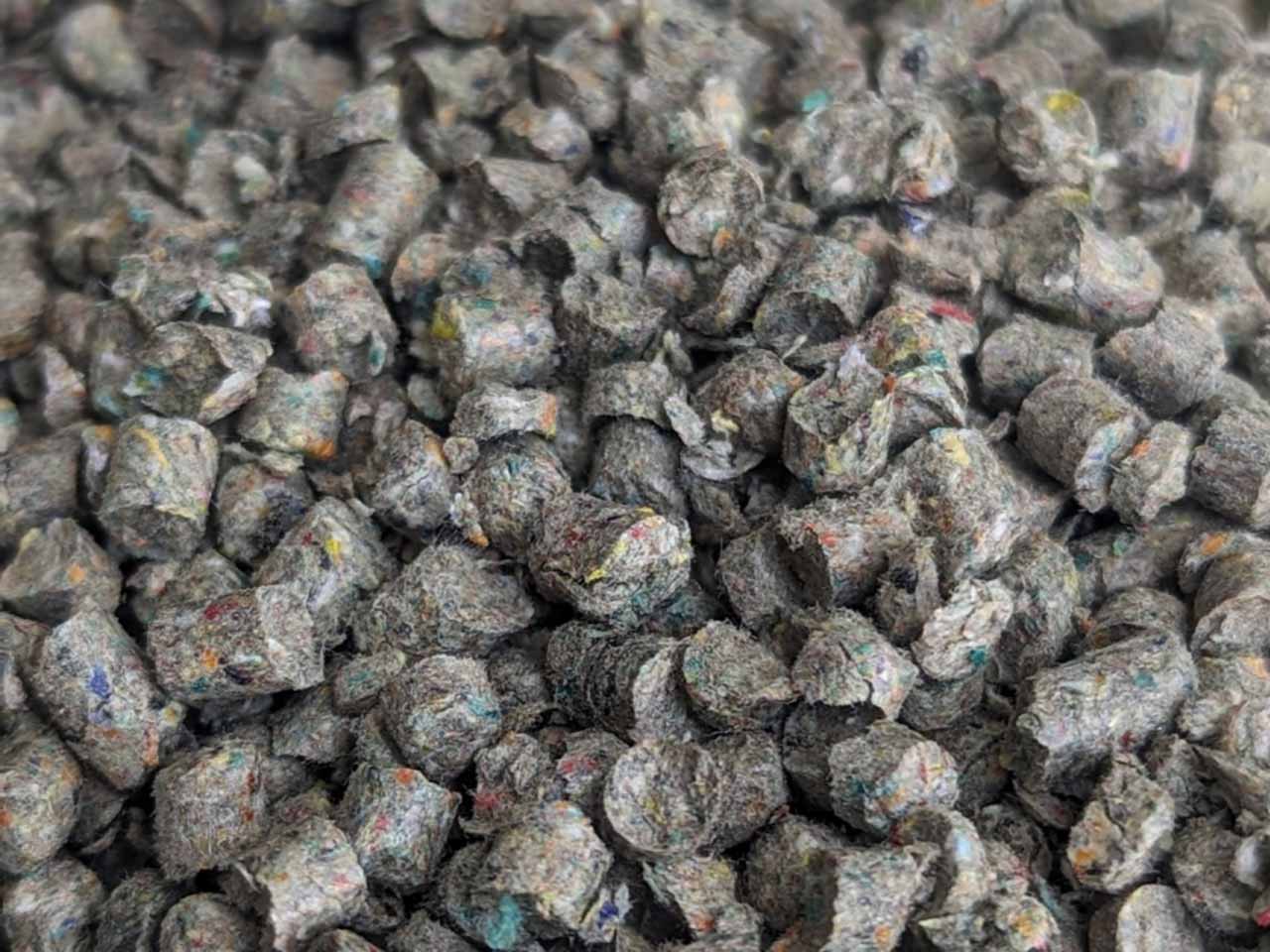

Granulation of the product

In order to transform the mix into compressed granules, we use an industrial granule press. It will compress the material through a matrix.

We regularly control the granules obtained, in particular their hygrometry and their density in order to ensure that the customer’s specifications are respected.

Post Production

Once the granules are made, we sort them out to remove any dust before conditioning them in bags and sending them to the clients.

We make sure to weep and clean thoroughly after each production so that the granulates don’t spill into nature.

Assessment – feasibility : 3 levels of service

You provide us with the formulation: carrier + active ingredients, and we offer :

- Homogeneous mixing.

- Granulation.

- Packaging.

- Quality testing.

- Homogeneity test.

- Feasibility study report.

- Industrialization.

Based on the active substance of the formulation you provide, FuturaMat offers you..:

- Search for carriers.

- Homogeneous mixing.

- Granulation.

- Packaging.

- Quality testing.

- Homogeneity test.

- Feasibility study report.

- Industrialization.

Based on your specifications and the desired functionality of the product, FuturaMat offers you :

- Search for supports.

- Research into formulations.

- Homogeneous mixing.

- Granulation.

- Packaging.

- Quality testing.

- Homogeneity test.

- Density control.

- Biodegradability analysis.

- Feasibility study report.

- Industrialization.

Once the feasibility study has been validated, FuturaMat offers you an industrialization service according to the defined specifications.

- Volume.

- Number of ingredients.

- Packaging.