Development of extruded materials

Formulation

Our research and development department is in charge of finding the right formulation to create a plastic material that meets our customers’ specifications.

Our formulations are based on a wide choice of biobased, biodegradable, and recycled raw materials, qualified according to our company’s protocols.

Processing of raw materials

In order to obtain a quality compound, each component of the formulation is preconditioned.

For this, we use a drying device that regulates the humidity level in order to create the required conditions for the extrusion of the material.

Compounding of the material

This is the most important step of the process, as it consists in transforming the components of the formulation into a compound, also called granules or pellets.

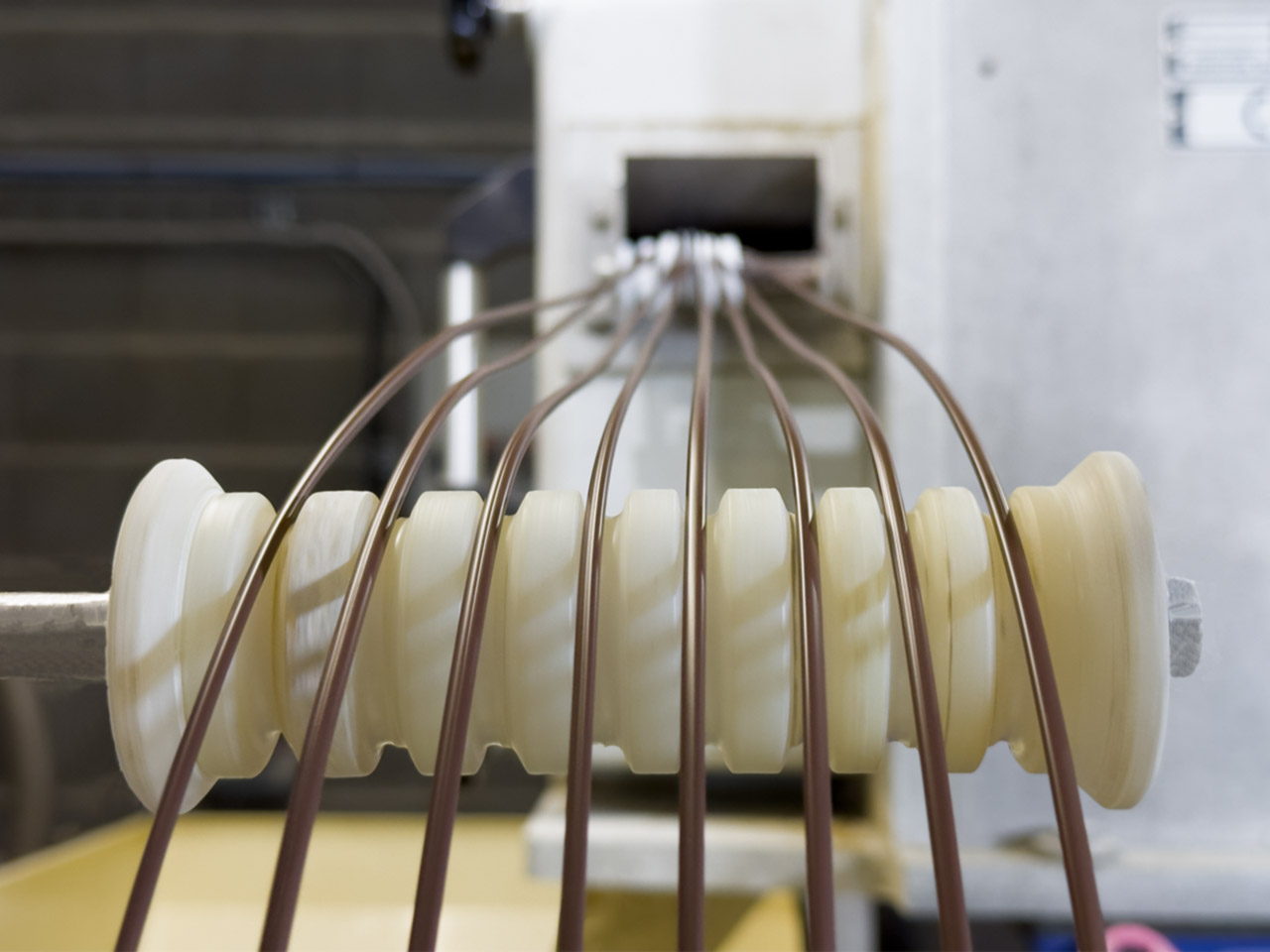

For this, we use a twin-screw extruder which allows a real alloying of the different components in order to obtain a homogeneous compound.

The rods thus obtained are cooled and sectioned to obtain a compound.

Quality control is then carried out to check the humidity, fluidity, and integrity of the compound in order to guarantee the conformity of the product to the specifications.

Post production

Once the pellets have been obtained, we sort them to eliminate impurities before packaging them.

We take care to carry out a complete cleaning after each production so that the pellets do not spread in nature. They are collected, screened and fed back into the production line as soon as possible.

Calendering

FuturaMat places its calender at your disposal to conduct pilot-scale trials.

Following the development of a new formulation for thermoforming, we offer the possibility of calendering the compound on our production site.

Our calender can handle winding sheets and plates of thicknesses ranging from 300µ to 2mm, with a maximum width of 450mm.

Discover our range of products

Through our experience in the plastics industry, we have developed a range of biosourced plastics composed of five main families: BioFibra®, BioCeres®, BioMine®, PolyFibra® and BioPolyme®.

Each of these families has specific characteristics such as biodegradability, composting, added wood or chalk, etc.

Our BioFibra® is made of biobased and compostable materials (biopolymers, wood flour, and plant-based additives).

Made from native wheat flour and biodegradable polymer, our BioCérès® references are biobased and compostable, but also OK Compost® and OK biobased®.

The BioMine® range is designed from biopolymers of vegetal sources to which added mineral fillers bring a soft touch aspect to the final product.

Made from the association of polypropylene and vegetal fibers, our PolyFibra® materials are adapted to the techniques of transformation by injection and extrusion.

References in the BioPolyme® range are made from a combination of compostable and partially biobased biopolymers.